While nanocars (single-molecule vehicle of hundreds atoms that incorporates a chassis, axles and freely rotating fullurene wheels and can be propelled across a gold surface by an electric current or heat) were invented in 2005 by Rice University, nano-enhanced cars are already among us!

The current automotive industry’s driving factors are to decrease vehicles fuel consumption and environmental impact while improving passengers’ safety and comfort. After focusing on solar energy and packaging, let’s see now how nanotechnology can help us having better cars! The prospects are both in bulk (nanocomposites) and in surface (application of nano-structured coatings or nanolayers).

Although sub-micro particles of carbon black or silica had been used as fillers for tire-rubber for decades, some say that Toyota invented nanocomposites (in fact, at least, the terminology), so it’s obvious that nano is not new to automotive! In fact the first nylon 6-clay nanocomposites were commercially used by Toyota in 1989¹. General Motor followed in 2002 for a step-assist. In 2004 Chevrolet reinforced a body side trim with nanoclays, and with a new part design, achieved a 25% weight savings. Maserati engine bay covers, were made with a nanocomposite were claimed to reduce the weight and increasing mechanical properties.Nano-Enhanced adhesives have also been reported to be used with success in improving bond strength.

In all such cases, the unique advantage of using nanofillers rely on the fact that they can increase both the polymer strength and impact resistance. As opposed to foaming or use of hollow fillers that lead to a light weighting but decrease load strength, nanofillers are still in development to reduce the weight of structural parts. Besides, the improvement in mechanical properties, fire retardancy, dimensional and thermal stability are also enhanced. Furthermore, nanofillers are effective at lower concentrations than traditional fillers used in automotive. Nanoclays are the dominant commercial nanofiller used in automotive. They can replace glass fibres at a 3:1 ratio, with an affordable cost. As such, nano-reinforced polyolefins are increasingly used in the sector.

In terms of surface application, nanoparticles are reported to be used in scratch-resistant and dirt-resistant paints for body or treatment for windshields and textiles. Indeed, fabrics are highly susceptible to wear, dirt, and fire. A wide array of nanotechnology-based textiles treatments can overcome these challenges and improve their performance and durability.

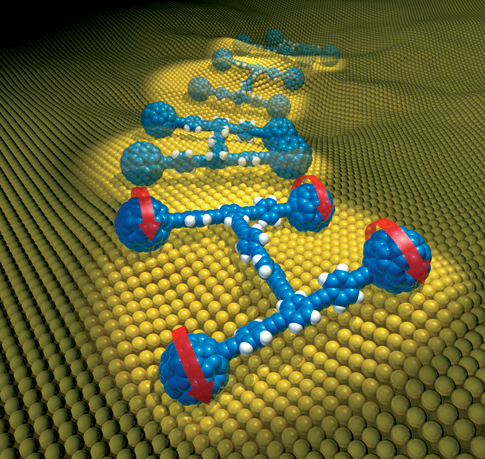

Besides, paints, coatings, tires, body parts with lighter but more durable/cleaner/stronger materials, the automotive can further benefit from the utilization of nanomaterials in terms of functional parts such as engines and powertrains, exhaust systems and catalytic converters, suspension and breaking systems, electric and electronic equipment, etc. Among the endless array of possibilities depicted in the image below, OptiNanoPro is especially focusing on the light weighting of large car parts to lead to a greater fuel efficiency for tomorrow’s car!

¹Okada and A. Usuki, “Twenty Years of Polymer-Clay Nanocomposites,” Macromolecular Materials and Engineering,vol. 291, pp. 1449-1476, 2006

Images from Fat Penguin and Hessian Ministry of Economy, Transport, Urban and Regional Development.