Optical systems to support the production of surfaces with advanced functionalities

Enhanced product performance through fine surface functionalisation requires process control beyond standard metrological practice. One of the first steps to digitalisation and Industry 4.0, is inline monitoring using in-process sensors.

In line with the progresses of photonic technologies, novel systems have proven effective for real-time detection of defects, deviations, or other anomaly and potentially to instigate corrective actions, thanks to modelling resulting in optimal quality and scrap minimisation among other benefits.

A consistent coating thickness is important to guarantee constant properties without using more resources than required. As such, monitoring is needed over a range of materials both laterally and across the samples. Different techniques can be implemented such as mechanical and ultrasonic gauges, and machine vision. They are widely used in the parts manufacturing industries to measure parameters such as surface topology, lining, paint or coating thicknesses.

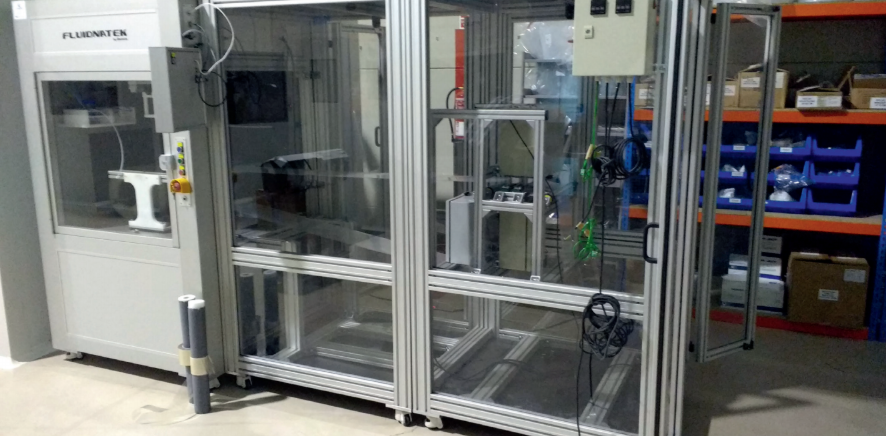

The EU project THIME has resulted in the development of an imaging spectral reflectance system, validated as an online quality control system to monitor thin film application in roll-to-roll organic photovoltaic (OPV) production processes.

The latest project OLEDSOLAR will further develop this system for closed-loop process control.

In the EU project OptiNanoPro, we developed systems suited to monitoring the application of transparent biopolymer nanocomposite coatings on transparent plastic films at high speed and polymer micro-textured surfaces.

You can have a look at the results of these projects and an interview to Elodie Bugnicourt, Research & Innovation projects expert, sustainable materials specialist at IRIS Technology Group in the following link.

It has first been published in European Coatings Journal, issue 06/2019.

“The integration into existing production lines is definitely feasible for SME”